Maintaining and Repairing Pallet Jacks – What to Watch For

January 30, 2023 | Pallet Jack Guidance

As a central workhorse in business logistics, the pallet jack is one of the most crucial material handling tools. Due to their significant role in logistical material handling, the demands on pallet jacks regarding workload and readiness are extremely high. Pallet jacks prove highly efficient when handled properly in warehouses, logistics, or other operational areas. However, under very high intensity of use, issues such as wear and tear or damage may lead to breakdowns, which need to be fixed to ensure the safety of operators and cargo. Problems like uneven wheel alignment or lifting and lowering malfunctions are common manifestations of breakdowns in pallet jacks.

Over time, certain measures have proven effective in maintaining the functionality of a pallet jack for an extended period. Some repairs are relatively straightforward to perform. Therefore, we will show you what to watch for in the maintenance and repair of pallet jacks and which repairs you can do yourself.

Pallet Jack Maintenance – Regularly Inspect Functionality with Care

To ensure the smooth functionality of the pallet jack and operator safety, the first step is to conduct regular inspections of the equipment. Performing a brief maintenance check once a week should suffice to assess the essential functions and the general technical condition of the equipment. We recommend using the following checklist, which will guide you through the key points of a brief, thorough inspection.

Maintenance Checklist for Pallet Jacks

- Are there any visible damages such as scratches, deformations, or cracks?

- Is the hydraulic oil level in compliance with the manufacturer's specifications?

- Do you notice external oil traces on the lines and cylinders, indicating a potential leakage?

- Are there dirt or foreign objects on the lift cylinder that may have been caused by faulty seals?

- Are there any issues with the lifting or lowering function of the pallet jack's hydraulic system?

- Are the wheels and casters in operational condition, or does their condition suggest an uneven operation?

- Is there a possible malfunction in electrical components (in the case of an electric pallet jack)?

- Do other functional features of the pallet jack exhibit errors, such as the braking function on a pallet jack with a handbrake?

FEM Inspection for a Pallet Jack

Regularly inspecting the above-mentioned points will improve the operational readiness of your pallet jacks in the long run and reduce the risk of failures that can negatively impact the efficiency of your operational logistics. Furthermore, regular maintenance of pallet jacks increases the likelihood of passing the FEM inspection without issues. This inspection is a legal requirement for material handling equipment and must be conducted at least once a year to ensure ongoing operational safety.

The inspection according to FEM standard 4.004 takes place at least once a year and checks the safety of the components of material handling equipment as well as their functionality.

Pallet Truck Mainentance – how can you repair a pallet truck yourself?

When a pallet truck experiences simple damage or malfunctions, these issues can often be repaired by oneself. Particularly with a pallet jack, repairs are typically relatively straightforward due to the simple technology and basic construction, as long as you have the right pallet truck spare parts. These types of repairs usually take only a short amount of time. For more complex damage that requires advanced technical knowledge, it is advisable to seek assistance from a professional workshop or contact the manufacturer. These providers typically have trained personnel capable of properly addressing and fixing such issues. Especially in the case of an electric pallet truck, due to the presence of electrical components and conductors, any malfunctions or damage should be addressed by the manufacturer's repair service or a specialized workshop.

Bleeding a Pallet Truck for Lifting and Lowering Issues

When you encounter obvious problems with the hydraulic system, such as the pallet truck's forks not lifting or lowering properly, it's often due to air trapped in the hydraulic system. Frequent tilting or uneven operation of the equipment is typically the main cause of improper functionality caused by air in the hydraulic unit. To resolve this issue, you need to bleed the pallet truck:

- Raise the pallet truck without any load. To do this, move the control lever to the lifting position and pump the handle with the tiller.

- Press the tiller all the way down until it stops and move the control lever to the lowering position.

- Hold the control lever in the lowering position and pump the handle with the tiller several times. This will allow the air in the hydraulic system to escape.

- Repeat steps 1 to 3 multiple times.

- Test the functionality of the pallet truck with a load.

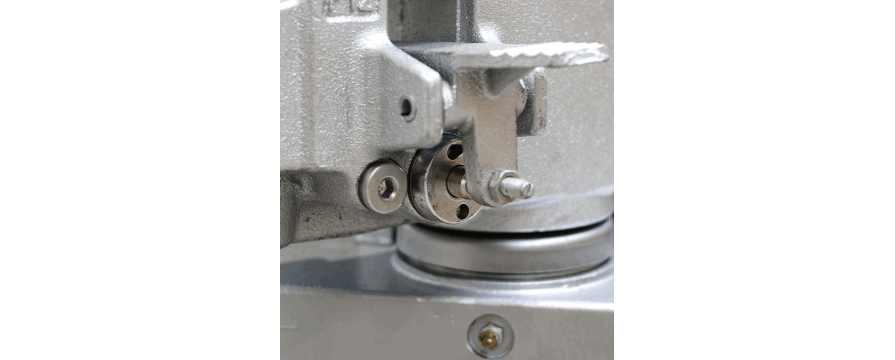

Adjusting the Lowering Valve for Malfunctioning Lowering Function

After successfully bleeding the hydraulic system, you should check the adjustment of the lowering valve on the pallet truck if the lowering function still doesn't work correctly:

- Required tools: open-end wrench (size SW14 / SW10) and screwdriver (slotted or with a 4mm hex head)

- Position the control lever on the tiller in the middle position.

- Loosen the locknut of the adjustment screw on the lowering valve (using the open-end wrench) and then unscrew the adjustment screw slightly by turning it to the left (using the screwdriver).

- The lifting hydraulics should now be in the middle position.

- Load the tiller with one hand to make the device raise the forks. Keep your hand on the tiller, and simultaneously, with your other hand, gently turn the adjustment screw inward until you feel the tiller's pressure point decrease in your hand (using the screwdriver).

- Once the pressure point has given way, tighten the screw a quarter turn back to the right to ensure the middle position function is restored. Then, reattach the locknut.

- Test the functions for lifting, middle position, and lowering.

- If the problem persists, consult a professional workshop or contact the manufacturer.

Refilling Hydraulic Oil in a Pallet Jack for Issues with the Lifting and Lowering Function

A low oil level can also lead to malfunctions in the lifting and lowering of the pallet jack's forks due to insufficient hydraulic pressure. Therefore, it's important to perform regular checks of the oil level and refill the oil if necessary. Here are the steps to follow:

- Tools required: Screwdriver and suitable hydraulic oil (ideally, use the same oil that is already in the hydraulic system or oil that meets the manufacturer's specifications).

- On a level surface, fully lower the pallet jack and place the control lever in the lowering position.

- Remove the oil fill plug (using a screwdriver).

- The oil level should ideally reach the bottom of the fill hole (the specific level depends on the device, and some units have an oil level indicator through a sight glass).

- Top up the oil to the required level (usually about 0.3 liters will be sufficient).

- Securely reattach the oil fill plug to ensure the sealing ring is correctly positioned between the plug and the housing.

- Pump the hydraulic system about 10-20 times to initially bleed any air from the system. After this, the pallet jack should smoothly lower the forks without issues.

- If the problem persists, seek assistance from a specialized workshop or contact the manufacturer.

A low oil level often results from an obvious or hidden oil leak. Therefore, the device should also be examined for potential leaks, especially in the hydraulic unit.

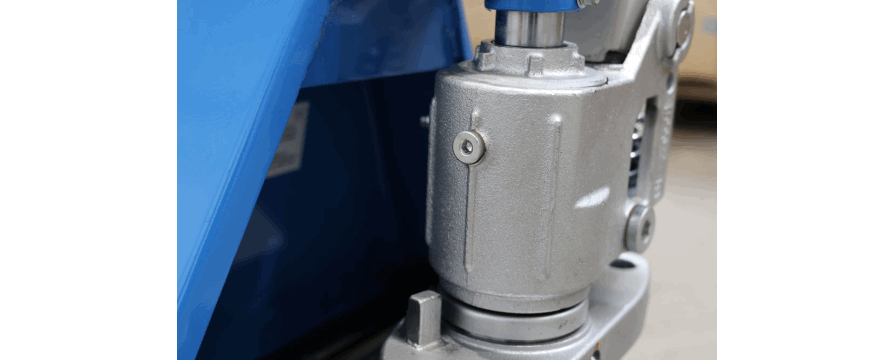

Performing an Oil Change on the Pallet Truck

Regularly changing the oil is one of the most critical tasks to ensure the equipment's smooth and long-lasting function. If there are contaminants in the hydraulic system, an oil change is absolutely necessary to prevent further damage:

- Required tools: slotted screwdriver, drift pin punch, hammer, socket wrench, catch container, and suitable hydraulic oil (ideally the same oil already in the hydraulic system or oil that meets the manufacturer's specifications).

- Lower the pallet truck completely on a level surface and move the control lever to the lowering position.

- Remove the oil filler screw from the hydraulic unit's housing (using a slotted screwdriver).

- Unhook the drain chain and loosen the retaining pin on the drain lever (using a drift pin punch) to be able to remove it.

- Rotate the tiller fully to gain unobstructed access to the lowering valve.

- Position a catch container beneath the lowering valve.

- Completely unscrew the lowering valve (using a socket wrench) and allow the oil to drain out gently. Make sure to absorb any spilled oil properly.

- Inspect the sealing ring (O-ring) of the lowering valve for damage. If there is damage, replace the ring.

- Reinstall and tighten the lowering valve and secure the drain lever with the retaining pin (using a hammer).

- Reattach the drain chain to the drain lever.

- Refill the oil to the required oil level.

- Attach the oil filler screw and tighten it firmly, ensuring the sealing ring is correctly positioned between the screw and the housing.

- To allow testing of the lifting and lowering functions, purge the hydraulic system initially by performing 10-20 pump strokes.

Replacing Load or Fork Rollers on the Pallet Truck

In daily use, the load or fork rollers of a pallet truck are subjected to significant stress, which leads to wear and tear over time. Therefore, when wear or damage occurs, it's necessary to replace the fork rollers on the pallet truck:

- Required tools: hammer, drift pin punch, grease, cloth/rag.

- Lay the pallet truck on its side to have clear access to the underside of the forks.

- Remove the retaining pin from the wheel housing (using a drift pin punch and a hammer).

- Fold down the wheel housing, pull the axle downwards, and remove the exposed wheel.

- Thoroughly grease the moving parts, following the manufacturer's instructions.

- Place the new wheels on the axle, insert them into the wheel housing, and secure the axle with the retaining pin (using a drift pin punch and a hammer).

- Return the pallet truck to an upright position and check the wheel behavior for smooth and unobstructed rolling.

Replacing Steering Wheels or Casters on the Pallet Truck

The steering wheel or caster is a heavily stressed component since it has to carry the load on the pallet truck and respond to the operator's steering commands. Over time, this stress leads to wear and tear. To ensure proper maneuvering and steering capability, worn or damaged steering wheels or casters must be replaced:

- Required tools: slotted screwdriver, external snap ring pliers, plastic hammer.

- Lay the pallet truck on its side to have clear access to the steering wheels or casters.

- Remove the protective cap from the steering wheel (slotted screwdriver).

- Remove the snap ring (external snap ring pliers) and then take out the washer.

- Remove the worn wheel from the axle and place the new wheel, ensuring that the washer is correctly positioned.

- Insert the snap ring into the axle groove (external snap ring pliers), and reattach the protective cap (using a plastic hammer).

- Return the pallet truck to an upright position and test its straight-line rolling behavior.