Maintaining and Repairing Pallet Trucks – What to Watch For

January 30, 2023 | Pallet Truck Guidance

As a central workhorse in business logistics, the pallet jack is one of the most essential material handling tools. Due to their significant role in the logistical material flow, the expectations for pallet jacks in terms of utilization and readiness are extremely high. Pallet jacks prove to be highly efficient when handled correctly in warehouses, logistics, or other operational areas. Nevertheless, under very high intensity of use, issues such as wear and tear or damage may lead to breakdowns that need to be fixed to ensure the safety of operators and cargo. Problems like uneven wheel alignment or lifting and lowering malfunctions are common manifestations of breakdowns in pallet jacks.

Over time, certain measures have proven effective in maintaining the functionality of a pallet jack for an extended period. Some repairs are relatively straightforward to perform. That's why we'll show you what to look out for when it comes to the maintenance and repair of pallet jacks and which repairs you can do yourself.

Pallet Truck Maintenance – Regularly Checking Functionality with Care

To ensure the proper functionality of the pallet truck and the safety of the operators, the first step is to perform a regular inspection of the equipment. Conducting a brief maintenance check once a week is sufficient to assess the essential functions and the overall technical condition of the equipment. We recommend the following checklist, which will guide you through the essential points of a brief and thorough inspection.

Maintenance Checklist for Pallet Trucks

- Are there any obvious damages such as scratches, deformations, or cracks?

- Is the hydraulic oil level in accordance with the manufacturer's specifications?

- Are there any external oil traces on hoses and cylinders indicating a leakage?

- Is there any dirt or foreign objects on the lift cylinder that may have resulted from faulty seals?

- Are there any malfunctions in the lifting or lowering function of the pallet truck's hydraulics?

- Are the wheels and rollers in functional condition, or does their condition suggest an uneven operation?

- Is there a potential defect in electrical components (in the case of an electric pallet truck)?

- Do other functional features of the pallet truck exhibit any issues, such as the braking function in a handbrake-equipped pallet jack?

FEM Inspection for Pallet Trucks

Regularly checking the points mentioned above improves the readiness of your pallet trucks in the long term and reduces the risk of failures that negatively impact operational logistics efficiency. Furthermore, regular maintenance of pallet trucks increases the likelihood of passing the FEM inspection without issues. This inspection is legally required at least once a year for material handling equipment and is essential for ensuring ongoing operational safety.

The inspection according to FEM standard 4.004 takes place at least once a year and checks the safety of the components of material handling equipment as well as their functionality.

Pallet Truck Repair – How to Repair a Pallet Truck Yourself?

If simple damages or malfunctions occur in a pallet truck, they can often be repaired by oneself. This is especially true for a pallet jack due to its less complex technology and simple construction with the right pallet truck spare parts, and typically requires only a small amount of time. However, more complex damages that require advanced technical expertise should be addressed by specialized workshops or by the manufacturer. In these places, usually, trained personnel are available to properly fix damages. Especially for electric pallet truck types, due to live components and components carrying electricity, it is advisable to have the manufacturer's repair service or a specialized workshop address any malfunctions or damages.

Pallet Truck Bleeding for Lifting and Lowering Issues

When obvious issues with the hydraulics arise, for example, when the pallet jack's fork is no longer lifting or lowering correctly, air has often entered the hydraulic system. Frequent tilting or uneven positioning of the equipment is typically the main cause of malfunction due to air in the hydraulic unit. To resolve the issue, the pallet truck needs to be bled:

- Raise the pallet truck without a load by moving the control lever into the lifting position and pumping with the handle.

- Push the handle all the way down to the stop and move the control lever into the lowering position.

- Keep the control lever in the lowering position and pump multiple times with the handle. This will allow air to escape from the hydraulic system.

- Repeat steps 1 - 3 several times.

- Test the functionality of the loaded pallet truck.

Adjusting the Lowering Valve for Malfunctioning Lowering Function

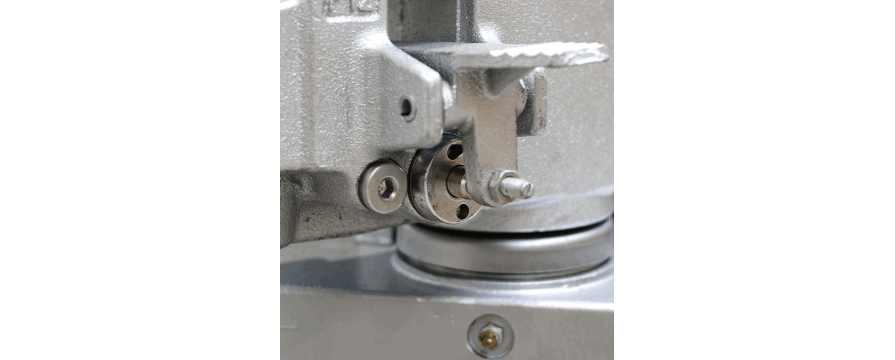

After successfully bleeding the hydraulic system as previously mentioned, you should check the adjustment of the lowering valve on the pallet truck if the lowering function continues to malfunction:

- Required tools: Spanner wrench (SW14 / SW10) and screwdriver (slotted or with a 4mm hex)

- Position the control lever on the handle to the middle position.

- Loosen the locknut of the adjustment screw on the lowering valve (spanner wrench), then turn the adjustment screw slightly counterclockwise (screwdriver).

- The lift hydraulics should now be in the middle position.

- With one hand, apply a load to the handle so that the device lifts the fork. Keep your hand on the handle and simultaneously gently turn the adjustment screw clockwise until you feel the handle's pressure point decrease (screwdriver).

- Once the pressure point has decreased, tighten the screw a quarter turn clockwise to restore the middle position function. Then, reattach the locknut.

- Test the functions for lifting, middle position, and lowering.

- If the problem persists, visit a specialized workshop or contact the manufacturer.

Refilling Hydraulic Oil in the Pallet Truck for Lifting and Lowering Issues

Low oil levels can also cause malfunction in the lifting and lowering of the forks due to low oil pressure. Therefore, regularly checking the oil level is necessary to be able to top up the oil when needed:

- Required tools: Slotted screwdriver and suitable hydraulic oil (ideally the same oil that is already in the hydraulic system or oil compliant with the manufacturer's specifications).

- On level ground, fully lower the pallet truck and put the control lever in the lowering position.

- Remove the oil fill plug (slotted screwdriver).

- Ideally, the oil should reach the lower edge of the fill hole (depends on the device), and on some devices, the oil level can be seen through a sight glass.

- Top up the oil to the required oil level (0.3 liters should be sufficient).

- Attach the oil fill plug and tighten it enough to ensure the sealing ring is correctly positioned between the plug and the housing.

- First, bleed the hydraulic system by pumping 10 to 20 times, then the pallet truck should lower smoothly.

- If the problem persists, visit a specialized workshop or contact the manufacturer.

Low oil levels are often the result of an obvious or concealed oil loss. Therefore, the equipment should also be inspected for possible leaks, such as at the hydraulic unit.

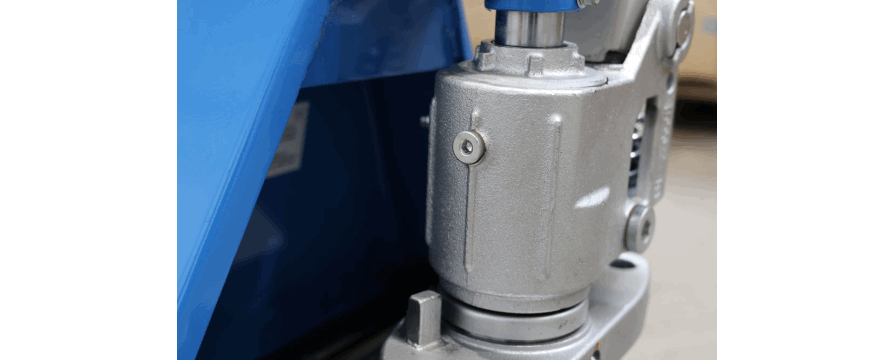

Performing an Oil Change on the Pallet Truck

Regular oil changes are one of the most critical tasks to ensure long-term trouble-free operation. If dirt particles are present in the hydraulic system, an oil change is absolutely necessary to prevent subsequent damage:

- Required tools: Slotted screwdriver, cotter pin driver, hammer, pin wrench, collection container, and suitable hydraulic oil (ideally the same oil that is already in the hydraulic system or oil compliant with the manufacturer's specifications).

- On level ground, fully lower the pallet truck and put the control lever in the lowering position.

- Remove the fill plug from the hydraulic unit's housing (slotted screwdriver).

- Unhook the drain chain and release the cotter pin on the drain lever (cotter pin driver) to remove it.

- Turn the handle all the way to gain clear access to the lowering valve.

- Position the collection container under the lowering valve.

- Completely unscrew the lowering valve (pin wrench) and gently let the oil drain. Ensure to contain any oil that might spill outside the collection container.

- Check the sealing ring (O-ring) of the lowering valve for damage. If damage is present, the ring must be replaced.

- Reinstall the lowering valve and tighten it. Then, also reinstall the drain lever and secure it with a cotter pin (hammer).

- Reattach the drain chain to the drain lever.

- Fill the oil up to the required oil level.

- Attach the oil fill plug and tighten it enough to ensure the sealing ring is correctly positioned between the plug and the housing.

- First, bleed the hydraulic system by pumping 10 to 20 times, then you can test the lifting and lowering functions.

Replacing the Load or Fork Rollers on the Pallet Truck

In daily use, the load or fork rollers of a pallet truck are subjected to high stress, which eventually leads to signs of wear and tear. Therefore, when there is wear or damage, it is necessary to replace the fork rollers on the pallet truck:

- Required tools: Hammer, cotter pin driver, lubricating grease, cloth/rags

- Lay the pallet truck on its side to provide clear access to the underside of the forks.

- Remove the cotter pin from the wheel mount (cotter pin driver and hammer).

- Fold down the wheel mount, pull the axle down, and remove the exposed wheel.

- Lubricate moving components adequately with grease, following the manufacturer's instructions.

- Place the new wheels on the axle, insert them into the wheel mount, and then secure the axle with the cotter pin (cotter pin driver and hammer).

- Reposition the pallet truck to an upright position and check the wheel's performance for smooth, unblocked movement.

Replacing the Steering Wheels or Casters on the Pallet Truck

The steering wheel or caster is a high-stress component as it has to support the load on the pallet truck and respond to the operator's steering commands. Over time, this stress leads to signs of wear and tear. To ensure maneuverability and steering capability, worn or damaged casters must be replaced:

- Required tools: Slotted screwdriver, retaining ring pliers (external), plastic hammer

- Lay the pallet truck on its side to provide clear access to the casters.

- Remove the protective cap on the steering wheel (slotted screwdriver).

- Remove the retaining ring (retaining ring pliers), then remove the washer.

- Take the worn wheel off the axle and place the new wheel. Make sure to correctly position the washer.

- Set the retaining ring into the axle groove (retaining ring pliers), and reattach the protective cap (plastic hammer).

- Reposition the pallet truck to an upright position and test its straight-line performance.